The Test Rig

This is the blog for the Test Rig

The Test Rig is a aluminium barge that will be used to test the components that will be used in the final boat.

The Test Rig will float in my pool, tethered to the side and fed power from the shore

The intention is to run all systems for at least two months, 24*7 to ensure all components can last the trip to New Zealand

26th August 2020

After giving up in frustration at my attempts to weld aluminium, I used nuts and bolts to assemble the propeller protection struts. The thruster has been attached to the rudder shaft and all the cables for the various components on the Aerial pole have been run into the Hull

Commencing the installation and commissioning of the internal components, starting with the Monitor and Comms CPUs

15th June 2020

The code for the calculations for collision avoidance are now working. This includes the relative course and speed of the two vessels and the likelihood of a collision

Now start the design of the algorithm of what to do in the that likelihood

29th May 2020

29th May 2020

After extensive programming efforts, in conjunction with my programmer wife, I can now read AIS and GPS messages from the QK-A028 receiver and process them to get values such as Latitude, Longitude, Course, Speed etc.

The Steering motor is now working, being driven from the ESP32 program

This now means that all components have been tested and working.

The next stage is more programming to integrate the systems, and to design and program the Collision Avoidance application

The Steering motor is now working, being driven from the ESP32 program

This now means that all components have been tested and working.

The next stage is more programming to integrate the systems, and to design and program the Collision Avoidance application

20th May 2020

Successfully tested the QK-A028 AIS Receiver.

Initial testing at my home in East Killara provided information sentences from the GPS unit, but no AIS data. A trip down to Balls Head ensued. The receiver, being close now to the harbour, picked up and relayed AIS sentences from many boats, including ferries. I was able to decode these sentences using a web based decoder (maritec.co.za/aisvdmvdodecoding1.php) to get the information.

The next step is to get an Arduino NMEA 0183 decode library so that I can decode the messages and make use of the information

Initial testing at my home in East Killara provided information sentences from the GPS unit, but no AIS data. A trip down to Balls Head ensued. The receiver, being close now to the harbour, picked up and relayed AIS sentences from many boats, including ferries. I was able to decode these sentences using a web based decoder (maritec.co.za/aisvdmvdodecoding1.php) to get the information.

The next step is to get an Arduino NMEA 0183 decode library so that I can decode the messages and make use of the information

12th May 2020

Successfully tested the Rockblock+ satellite transceiver. It is now supplying the satellite date/time to the Thingspeak display

Starting work on the AIS collision avoidance system.

The first step is to get the required data from the AIS receiver. This provides boat and GPS data in NMEA 0183 format. This format requires decoding to get the information I require.

The second step is to code the logic to take the relative positions for my boat and any other boats in the vicinity and decide if evasive action is required and if so what action

Testing the Rockblock+ satellite transceiver. The wheels under the hull are not attached, but make it easier to move the hull out of the garage for testing apps that use one or more of the aerials

Starting work on the AIS collision avoidance system.

The first step is to get the required data from the AIS receiver. This provides boat and GPS data in NMEA 0183 format. This format requires decoding to get the information I require.

The second step is to code the logic to take the relative positions for my boat and any other boats in the vicinity and decide if evasive action is required and if so what action

|

| Testing the Rockblock+ satellite transceiver. The wheels under the hull are not attached, but make it easier to move the hull out of the garage for testing apps that use one or more of the aerials |

7th May 2020

4th May 2020

A frustrating week with a variety of compass boards finally resulted in the bno055 board working successfully.

Awaiting some more RS232 devices to arrive. These are used with the Comms cpu to talk to the Rockblock+ satellite device. Once this is up an running, the comms/power board pictured below will be installed in the Test Rig and power supplied. This is the first major step in commissioning the Test Rig

The cables from the Comms mast have been fed into the Test Rig hull through waterproof cable glands

Ordered epoxy resin to encase the bno055 electronic compass, so that it can sit on the Comms mast, away from magnetic disturbances

Awaiting some more RS232 devices to arrive. These are used with the Comms cpu to talk to the Rockblock+ satellite device. Once this is up an running, the comms/power board pictured below will be installed in the Test Rig and power supplied. This is the first major step in commissioning the Test Rig

The cables from the Comms mast have been fed into the Test Rig hull through waterproof cable glands

Ordered epoxy resin to encase the bno055 electronic compass, so that it can sit on the Comms mast, away from magnetic disturbances

17th April 2020

After returning from holidays, work has recommenced

The Comms mast has been installed on the hull and the hole cut for the steering mechanism

The Comms and Power monitoring CPUs are now communicating via the serial Port. The other CPUs will talk via WiFi using ESP-Now

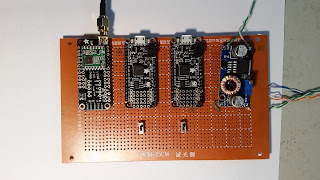

Building the board for the Comms and Power CPUS and associated sensor boards

Once this has been tested OK, a PCB will be designed and ordered

Working on the Satellite Comms from the Comms board and programming for monitroing the 12V and 5V power supplies

27th December 2019

The welding for the hull has been completed. Here is the hull ready to have components installed

Here is the steering mechanism. It consists of a worm drive and electronics to detect the rotation and control the start and stop locations of the drive shaft. This is transmitted via the panto-graph like linkage to a rod that will have the T200 motor attached to a plate at the bottom of the shaft

Here is the communications tree. It currently has the WiFi antenna for local ( to the house) comms, GPS antenna, AIS antenna ( for collision avoidance) and RockBlock+ Satellite system for data transmission when at sea. To be attached is the electronic compass, which will be encapsulated in epoxy for water tightness

8th November 2019

The hull has been bent to shape and the front seams have been welded (not very professionally)

I have been waiting for a TIG welder to arrive to weld the rear panel of the hub and to start constructing the various pieces for the steering, motor mount etc.

The welder should arrive next week, and I can then restart the construction phase

The power for the boat will come from shore. Here is the completed and tested 12V power supply unit. This will feed power via a cable that will be inside the connecting tube from the poolside to the boat

The 12V to 3.3V power supply and the power monitoring circuitry has been completed and tested.

At the moment it sends data via Wifi to Thingspeak. I am in the process of adding a CAN bus board to enable data from all components to be channelled to one wifi cpu, rather than having multiple aerials

Comments

Post a Comment